How the “Chalta Hai” Mindset Turns Micro-Stoppages into Major Breakdowns #

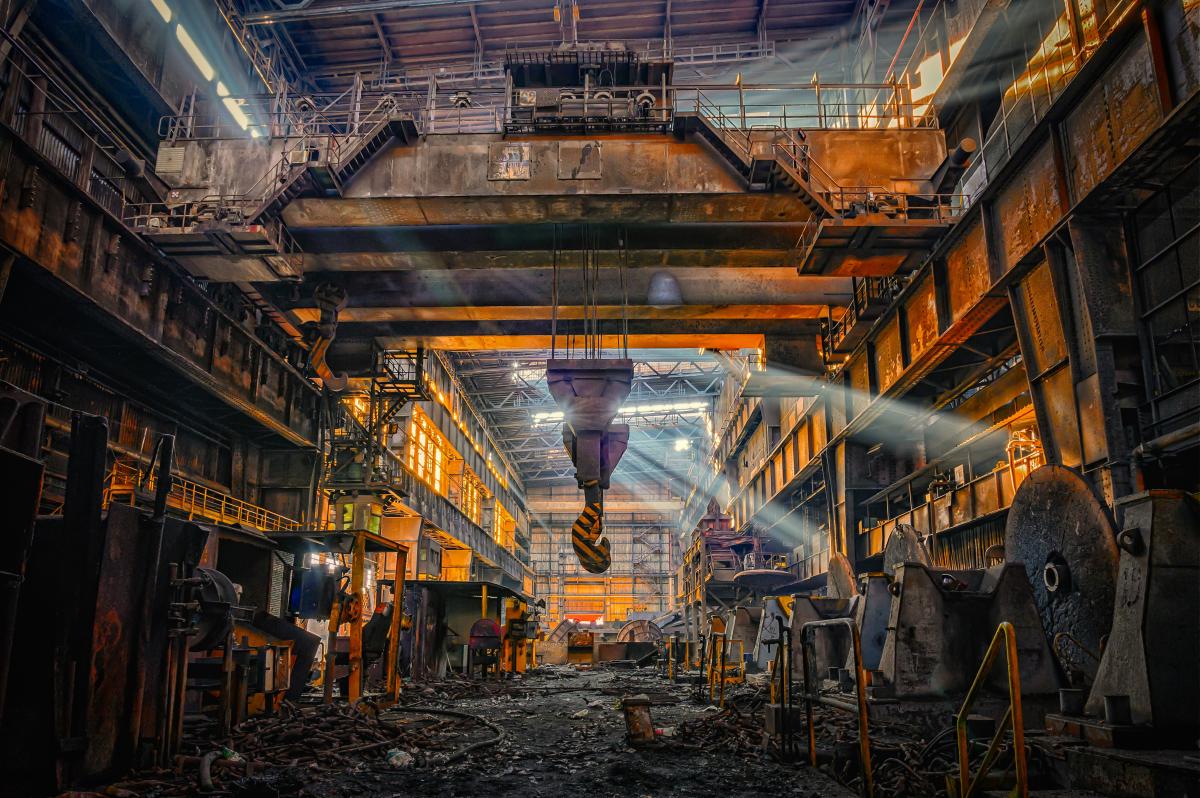

When a rolling mill stops for 4 hours due to a major breakdown, everyone reacts.

Management floor pe hota hai.

Engineers full pressure me hote hain.

Focus 100% hota hai.

Downtime ko serious liya jaata hai.

Par jo cheez mill ko actually weak karti hai, uska reaction rarely hota hai.

That is the daily “Chalta Hai” mindset towards micro-stoppages.

The Real Problem Is Not the Big Breakdown #

Big breakdown ek event hota hai.

Micro-stoppages ek habit ban jaate hain.

- 2 minute ka cobble

- 3 minute guide adjustment

- 4 minute billet heating delay

Sab bolte hain:

“Chalta hai, chhota sa kaam hai.”

Par process me chhota kuch bhi nahi hota.

Let’s Do the Real Math (No Excuses) #

Agar:

- 2 minutes ka delay

- 30 baar hota hai

- Across 3 shifts

Toh aap sirf time nahi kho rahe.

Aap kho rahe ho:

- Yield

- Energy efficiency

- Rolling stability

- Team discipline

Maine personally dekha hai: “Chote-chote stops hi bade losses ka root cause bante hain.”

Why Micro-Stoppages Are More Dangerous Than Breakdowns #

Breakdown ke baad:

- Root cause hota hai

- Action hota hai

- System improve hota hai

Micro-stoppages me:

- Koi RCA nahi hota

- Koi ownership nahi hoti

- Same problem repeat hoti rehti hai

Aur dheere-dheere: Breakdowns normalize ho jaate hain.

The Shift You Need: From Reaction to Control #

High-performing mills fast nahi hoti.

Wo stable hoti hain.

Aur stability aati hai discipline se, speed se nahi.

4 Practical Principles That Actually Work #

1️⃣ “Why” Over “Who” #

Jab micro-stoppage ho:

- “Who did this?” mat poochiye

- “Why did this happen?” poochiye

Use 5 Whys:

- Cobble kyun hua?

- Guide misaligned kyun thi?

- Check kab last hua?

System problem ko system se hi solve kiya jaata hai.

2️⃣ Leveling Discipline Is Non-Negotiable #

Agar:

- Furnace discharge temperature ±20°C fluctuate karta hai

Toh:

- Power consumption badhega

- Roll wear increase hoga

- Guides aur bearings pe stress aayega

Consistency = Profit

Variation = Loss

3️⃣ Predictive > Reactive (Har Baar) #

Agar aap bearing tab change karte ho jab:

- Noise aa rahi ho

- Vibration feel ho

Toh aap already late ho.

Strong mills:

- Failure ke pehle act karti hain

- Breakdown ke baad nahi

4️⃣ Standardization = Stability #

Agar:

- Har operator mill alag tareeke se set karta hai

Toh:

- Quality ek gamble ban jaati hai

- Process control impossible ho jaata hai

Standard setup = repeatable output

The Real Truth About Production Speed #

High production ka matlab:

“Mill ko fast chalao”

yeh nahi hota.

Real rule:

80% speed + zero micro-stoppages

will always beat

100% speed + 30 interruptions.

A Simple Question for Leaders #

Aaj agar aap apni mill dekhein,

toh sabse zyada hidden time-waster kya hai?

- Guides?

- Heating inconsistency?

- Maintenance response?

- Operator setup variation?

Yahin se improvement start hota hai.

Practical Micro-Stoppage Control Checklist #

(Use this even without external help 👇)

Fill This Form or Dm me on Whatsapp:+91 9897122597